CDR Eco Movement Inc., a digital equipment BPO company, has developed the “C-DreAm ” series of fully automated equipment that uses robots to perform used smartphone refurbishment and merchandising, and an automatic grading system that uses AI image recognition technology. This service will be available from August 2023.

Our Company has provided comprehensive solutions tailored to customer needs, including complete data erasure, inspection, and kitting services for the remaining data of many IT devices in general, including smartphones, PCs, and servers.

Among these services, in order to supply stable services to customers in the used smartphone market, where demand is growing, we have developed CDR Eco Movement’s proprietary system (C-DreAm), which incorporates our accumulated know-how on refurbishment, and offers complete data erasure, functional and Cosmetics inspection, and grading process We will sell automated equipment for data erasure, functional and Cosmetics inspection, and grading processes.

In recent years, highly functional smartphones with a variety of features have been launched to meet the changing needs of increasingly diverse customers. On the other hand, the number of inspection items in the used smartphone refurbishment process has increased and become more complex, and manual inspection has caused inconsistencies in work quality, which has become a major issue.

“C-DreAm” has succeeded in fully automating the process by absorbing the manual work and flexibly responding to new inspection requirements in the future. In addition, the system can accommodate smartphones with different operating systems, sizes, and shapes, and inspection items can be customized according to customer needs.

Processing performance is up to 880 units per day for 22 hours of operation, and our proprietary image recognition technology incorporating AI is used for appearance grading.

Summary of the equipment

Data Erasure

Similar to manual operation, terminals arranged on trays are fed into the C-DreAm, the distance between the terminals on the tray is recognized by image recognition of a camera attached to the robot, and the size and shape of the terminals are determined while removing them one by one to achieve mixed production of iPhones and androids. The system can also automatically recognize the shape of smartphone connectors, making it possible to accommodate future changes in the shape of the terminals. Date erasure is also supported by Blancco software, which has the highest level of erasure in the U.S., and factory reset by Apple Configurator.

Functional Inspection

A terminal with a dedicated inspection application installed is fed into the inspection device, and inspection is performed through communication between the application and the device. According to our standards, inspections of 25 items are performed automatically. The robot also performs finger movements that until now could only be performed manually, such as scrolling and touching the screen with a finger, so it can handle inspection items that vary from version to version. In addition, since inspection items can be set for each customer, the robot can respond to any increase or decrease in inspection items for each model.

Cosmetics Inspection

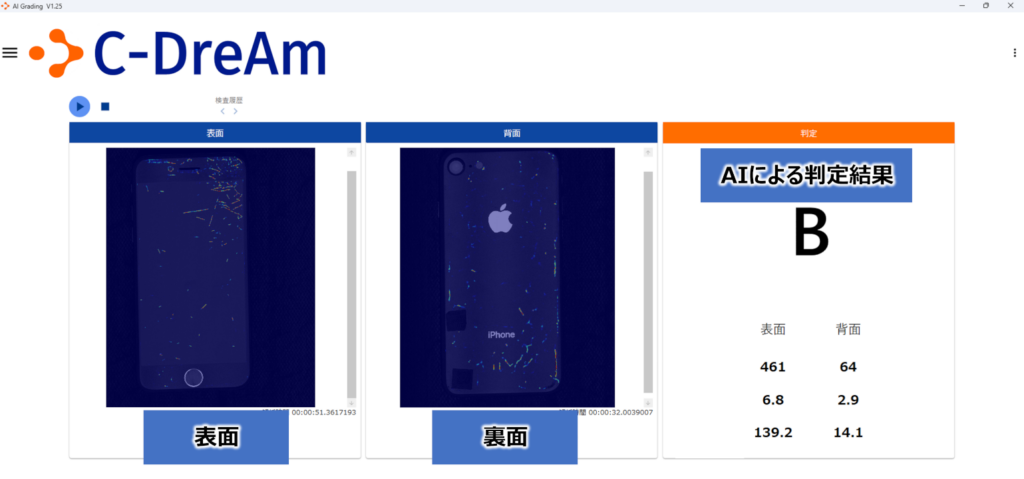

A sophisticated camera can detect not only large scratches that can be seen visually, but also fine scratches that are difficult to see even for experienced operators, and scratches deep inside the LCD. Scratches are detected not only on the front and back surfaces, but also on the edges, eliminating variations in work quality. Further research is underway to enable imaging of four sides and four corners in the next version. In addition, the system can realize our original automatic grading system by image recognition, which incorporates AI for appearance inspection.

AI automatic grading system

Our unique image recognition grading system incorporating AI automatically determines flaws and dents and has succeeded in automatically determining the level of flaws, which has been considered difficult to do so far. The determination accuracy has reached over 95%(※). Conventional AI requires more than 10,000 images of flaws for machine learning, which takes about two days of learning time, but the newly adopted AI can determine flaws with only about 100 images, which significantly reduces the learning time. ※Our standard

Our Company Through “C-DreAm,” we will continue to develop more automated equipment to contribute to the improvement of work quality and cost reduction at our customers. We will also steadily contribute to the achievement of the 『SDGs』 and the 『Circular Economy』 by promoting ESG management, aiming to realize sustainability for the earth, society, and people in the recycling and reuse of materials.